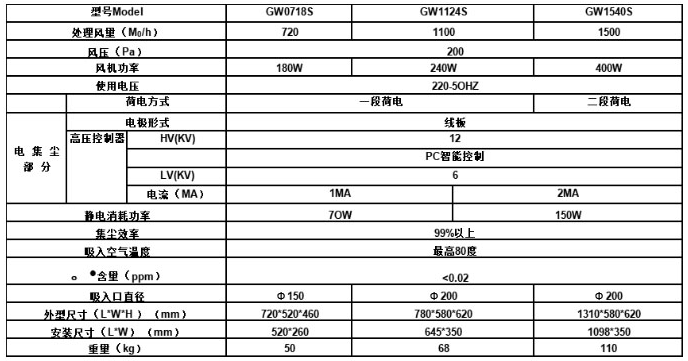

GW0718S

180W

220-50HZ

200

70W

Φ150

720*520*460

50

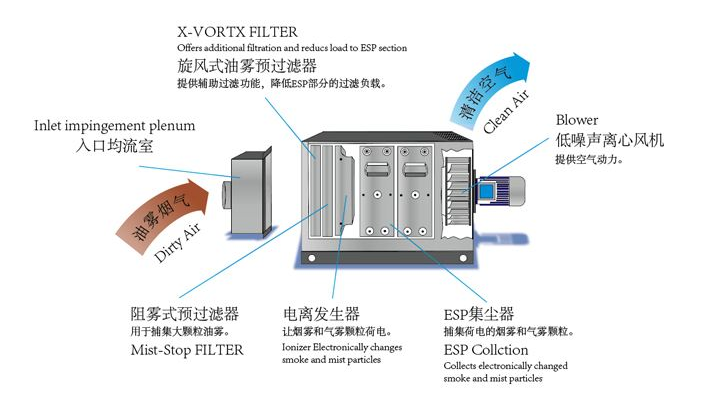

Electrostatic oil mist collector technology from Europe, combined with the actual situation of China to improve and upgrade, to achieve dedicated for the machining industry and smoke

The double function of oil mist collection and recovery, this product can purify and collect all kinds of smoke, including acid gas, alkaline gas, the collection efficiency is greater than 99%, the minimum filtration accuracy is 0.01um,

Convenient maintenance, simple and low cost, it is the best choice for the clean production of the factory in the machining industry to protect the health of employees.

Product technical features:

1. High efficiency: efficiently capture oil mist particles of different particle sizes, high purification efficiency, fundamentally solve the problem of pollution transfer.

2 flexibility: modular purification unit can be flexibly combined, according to different purification capacity and purification rate requirements, the number of units can be adjusted adaptively.

3 convenience: modular purification unit adopts separate drawer structure. Easy to install, maintain and clean.

4 advanced: electrostatic power control system can automatically adjust the electric field intensity, so that the purification equipment after long-term operation still maintain a high purification rate.

5 safety: the safety system is well designed. When the overhaul door is opened, the high voltage power supply will be automatically cut off. Safe and reliable use.

6 stability: static power control system with over - current voltage automatic protection device. Ensure the stable operation of the equipment.

7 economy: long service life, high energy saving (more than 60% energy saving than traditional technology)

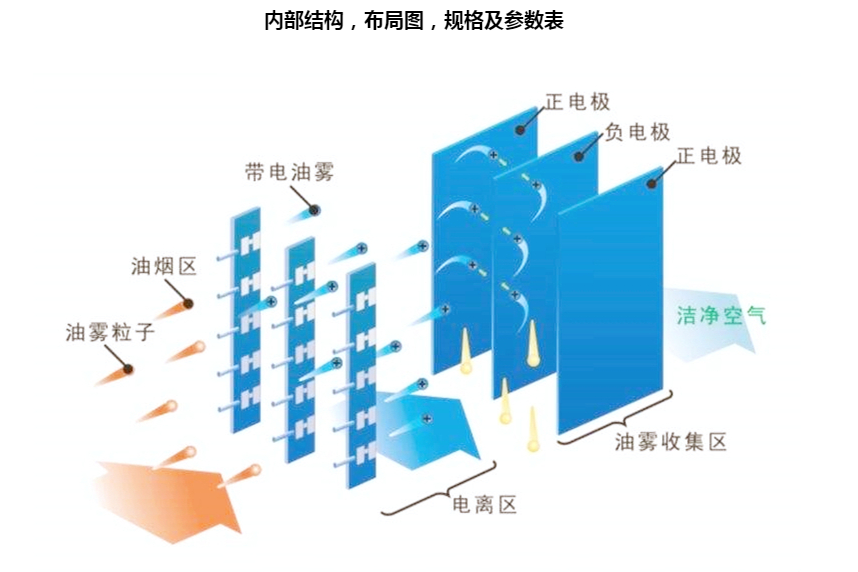

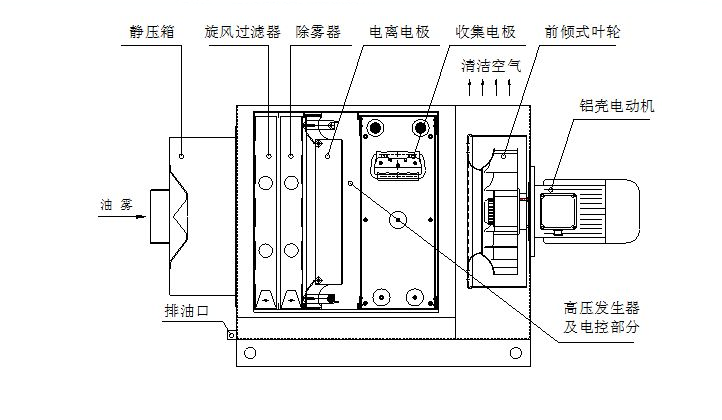

Centrifugal separation principle:

Adopt physical shielding technology. Using fan gas power to purify oil fume. The separation of oil fume in impeller was realized by the bidirectional flow theory of fluid mechanics. By changing the Angle of the blade and the form of the blade, the soot molecules collide and gather on the impeller disc and the blade. The oil fume is a particle oil mist, which is thrown into the inner wall of the box by centrifugal force and discharged from the oil leakage pipe.

High efficiency filtration principle:

After the front-end treatment, most of the oil smoke is removed, while the escaped micron oil smoke is filtered by the high efficiency filtration section (coarse filtration and fine filtration) after treatment. The remaining sub-micron oil mist particles and flue gas in the toxic and harmful substances and odor into the low temperature plasma purification section treatment.

This section has the function of sound absorption and noise reduction in filtration and purification. The overall noise of the equipment is effectively controlled.

Purification principle:

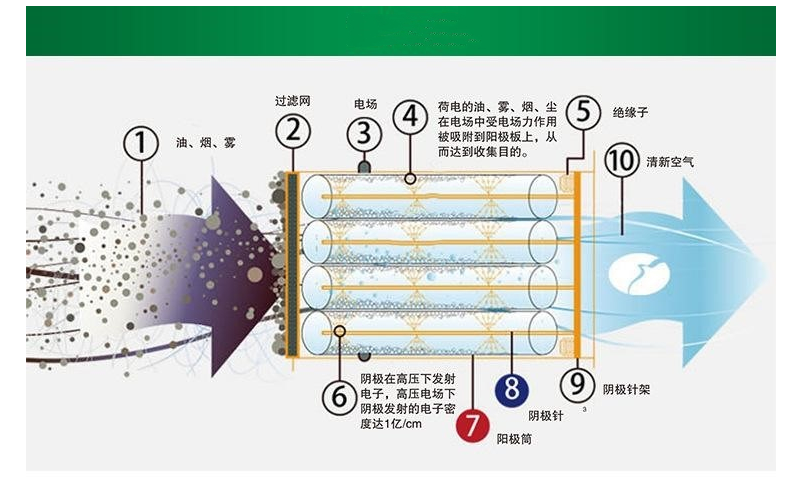

This section mainly uses electric field discharge method to generate high concentration of ions, and then uses plasma to make particles in the flue gas through the electric field with different (positive and negative) charges. Thus self-phase attraction, coagulation, single volume increases to gather into a large group and settlement, so that the flue gas is purified, can be as small as sub-micron fine soot particles for effective collection. It is different from the purification method of using electric field plate to adsorb lampblack particles directly by electrostatic type, which can prolong the effective working time of electric field and achieve low carbon operation.

Plasma is a kind of aggregated substance. When high-energy electrons collide with molecules in lampblack, a series of elemental physicochemical reactions will occur, and various active free radicals and ecological oxygen, as well as atomic oxygen produced by decomposition of ozone, will be generated in the reaction process. Active free radicals can effectively destroy nucleic acids and proteins in all kinds of viruses and bacteria, so that they cannot carry out normal metabolism and biosynthesis, and thus die. The ecological oxygen can quickly decompose the soot molecules into gases or reduce them to low molecular harmless substances.